Turbine Inlet Air Cooling (TIAC)

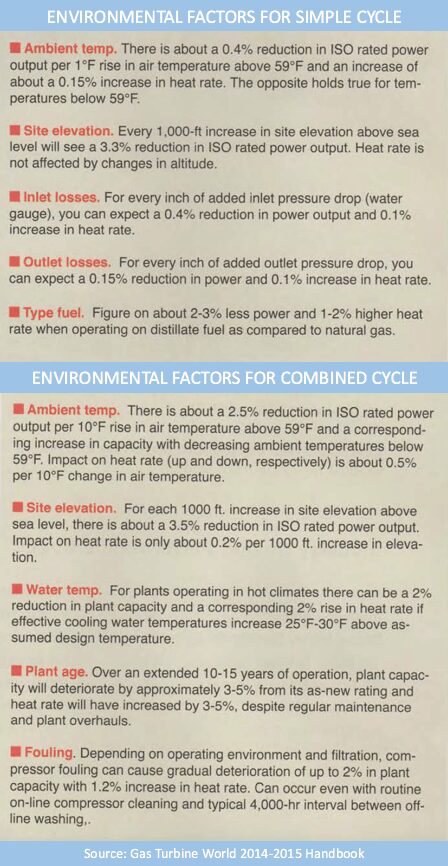

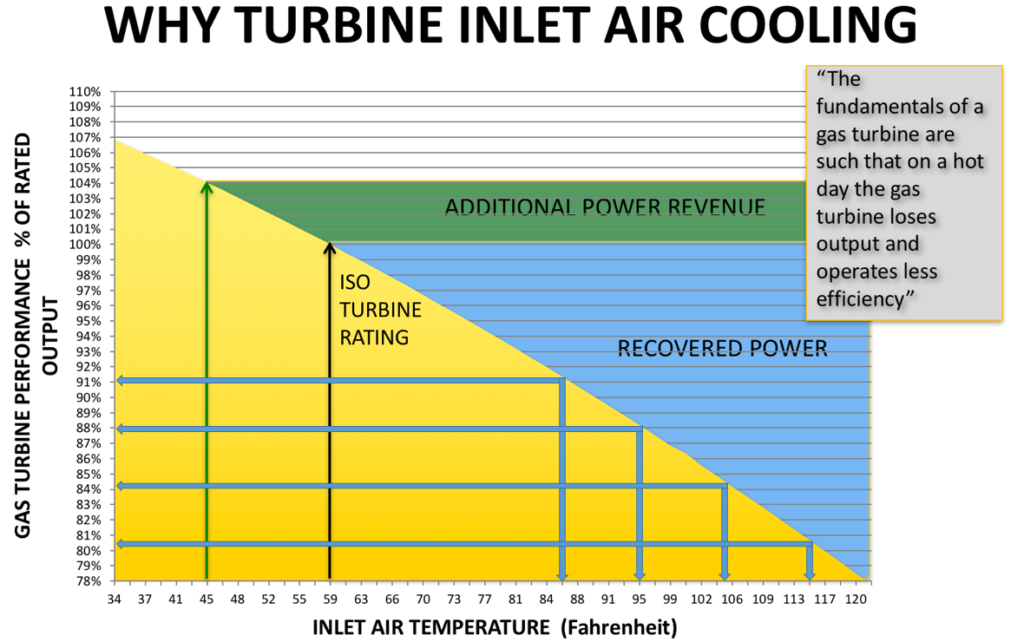

Natural gas-fired power plants, new or old, often operate at temperatures and altitudes above ISO conditions, thereby losing up to 25% of the power plant output.

Operating above sea level has a more dramatic reduction, dropping output by approximately 3.3-3.6% for every 1,000 feet in elevation! This means lower revenue and profits. This applies to both Simple Cycle and Combined Cycle Plants.

Turbine Inlet Air Cooling and its benefits are well proven in the market.

Turbine Inlet Air Ambient Temperature and Altitude affects the output of Gas Turbine power-generation, as visible from the graph below. In a tropical or desert environment, the average temperature can range up to 100 deg F and in peak may increase up to 120 deg F. Gas Turbine Net Output reduces drastically, just as the necessity for electricity peaks.

ENRGISTX strategic solution partners

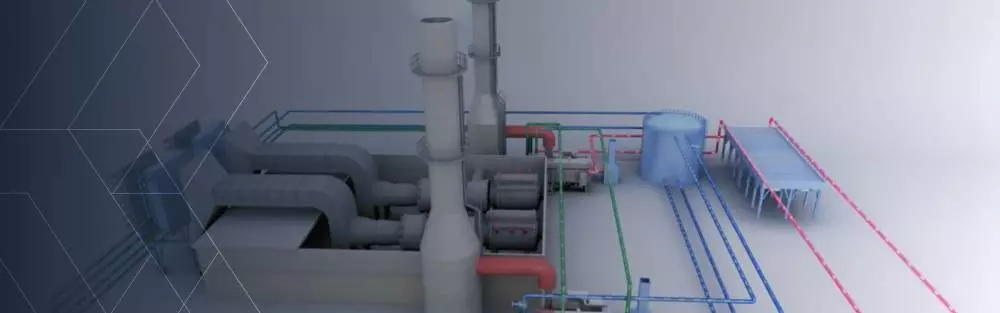

Cooling air with refrigeration systems can cool the inlet air to a temperature lower than the wet-bulb temperature and is the most effective method to maintain ISO design conditions.

ENRGISTX strategic solution partners are industry leaders in Turbine Inlet Air Cooling solutions utilizing Shuangliang Eco-Energy Absorption Chillers.

The solution to this problem is to cool (chill) the air entering the Gas Turbine to increase the output back to and even beyond the ISO specific performance, thereby improving operating efficiency and reducing carbon emissions.