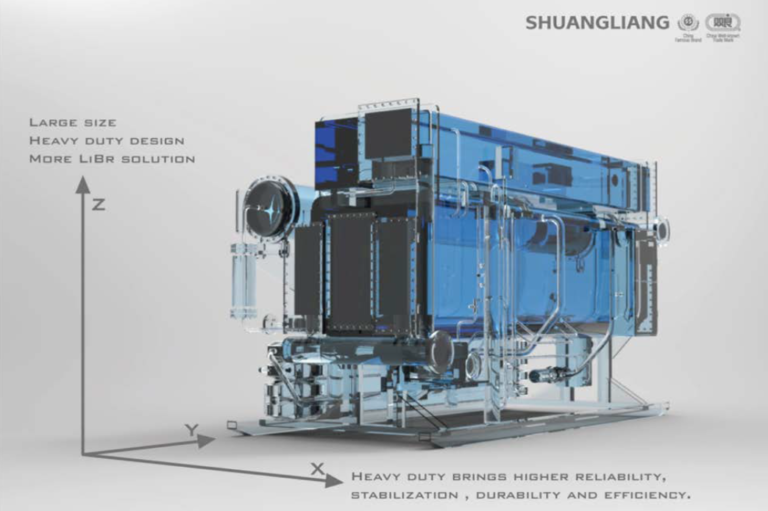

Leading Manufacturer of Absorption Chillers

COOLING CAPACITY FROM 99 TONS TO 3,300 TONS

CHILLED WATER SUPPLY TEMPERATURES AS LOW AS 23°F

Shuangliang Eco-Energy is the World Leader in industrial absorption chillers, with over 30,000 installations in over 30 countries.

Over 35 years in production and over 500 patents, Shuangliang Eco-Energy absorption chillers have many unique features that have proven to deliver key benefits over alternative manufacturers.

316 Stainless Steel (S316L ASTM S31603) High Efficiency & Reliable Heat Transferring Tube Design

Cooling water heat exchange tube uses a smooth pipe, which is resistant to scale, easy to clean, and avoids the disadvantages of rapid cooling of the high-efficiency pipe.

The heat transfer surface of the evaporator refrigerant water adopts high-efficiency large bellows, which are favorable for uniform liquid distribution and has high evaporation efficiency.

According to the characteristics of steam and solution, the generator adopts a high-efficiency heat exchange tube, which has high heat exchange efficiency, safety, and reliability.

It can meet the requirements of industrial users, adopt various stainless steel heat exchange tubes, and special expansion joint technology to ensure the reliability of the unit.

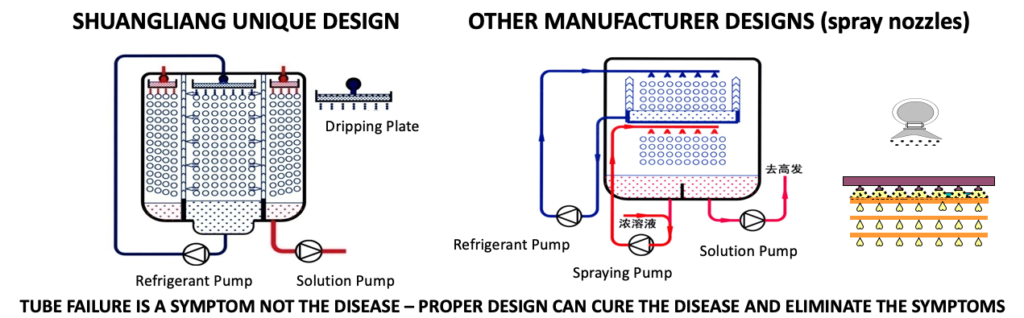

SHUANGLIANG Patented Dripping Plate design, utilized in both the Absorber and Evaporator sections, results in more even distribution of refrigerant, leading to higher chiller efficiencies.

Spray Nozzles used by other brands are subject to erosion and clogging, resulting in uneven solution and refrigerant distribution and potential tube erosion due to concentrated spray areas.

This problem is eliminated due to our unique Dripping Plate technology.

SHUANGLIANG Self-Cleaning Solution Design

The Absorber solution reservoir with a built-in filter on top, and a sump at the bottom, stage-wise filter solution.

The Absorber solution distribution pipe adopts a self-cleaning upper hole overflow mode, and the impurity particles in the solution do not enter the liquid discharge tray.

The Absorber and the Evaporator utilize the dripping plates with a built-in strainer, the number of shower holes is large, the liquid distribution is uniform, and never becomes blocked.

This design eliminates the liquid spray nozzle of other manufacturers, completely solving the problem of cooling capacity falloff among the whole industry, and prolonging tube life.

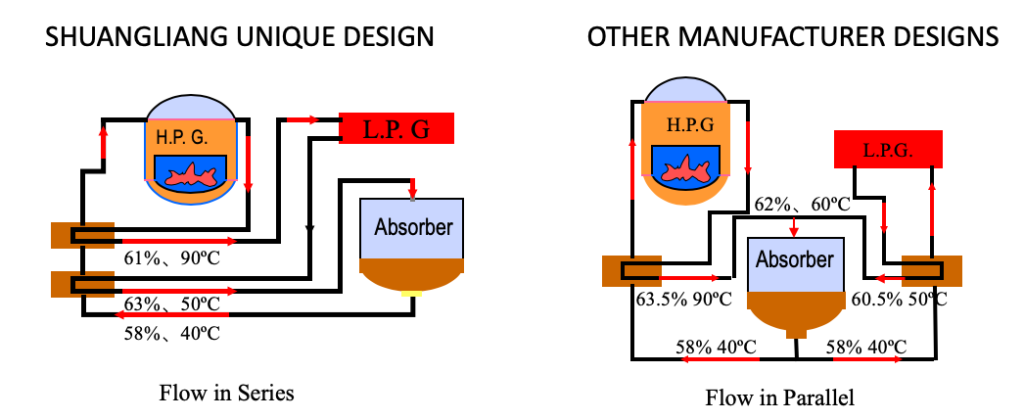

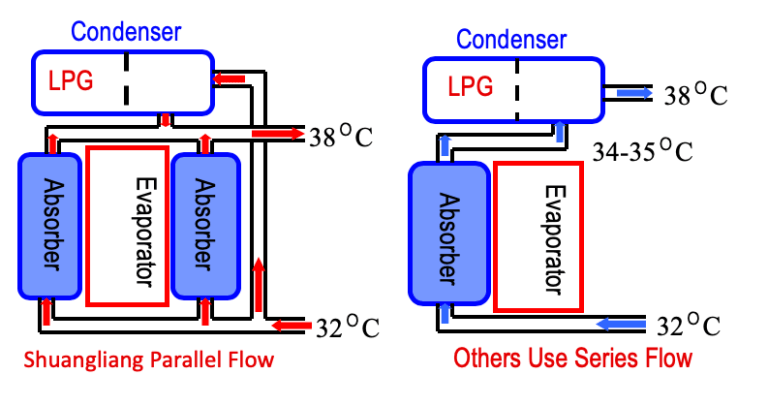

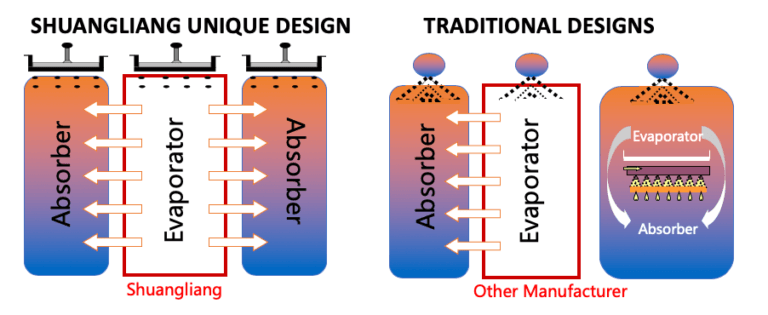

Serial Solution Flow Design vs. Parallel Solution Flow

SHUANGLIANG SERIAL SOLUTION FLOW Provides improved control over solution flow rate and concentration of LiBr solution, reducing the risk of crystallization.

Serial Flow design enables the chiller to be custom designed and fitted for the specific application where varying parameters can be taken into consideration. These include heat source temperature and pressure drops, chilled water, and cooling water temperature variations.

ENRGISTX

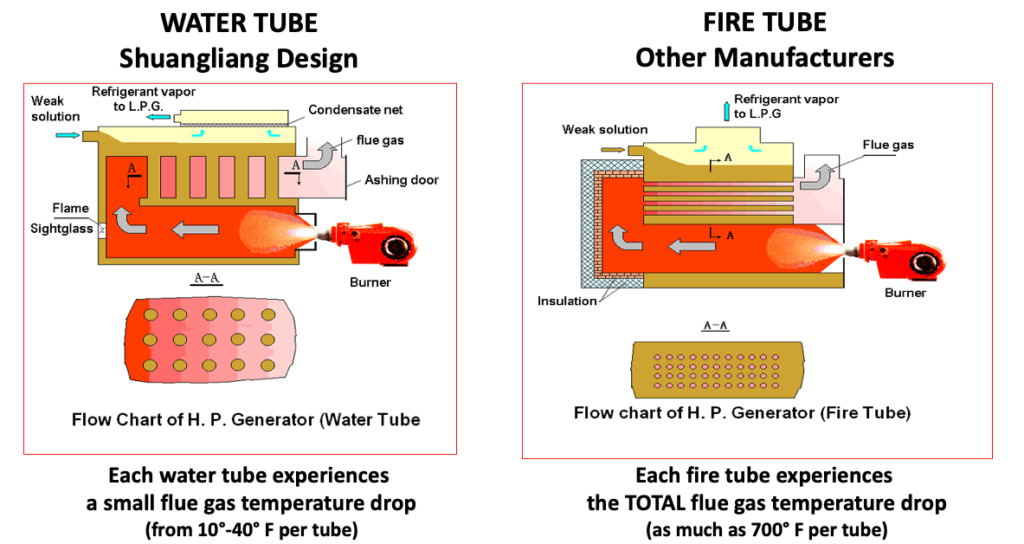

SHUANGLIANG WATER TUBE HIGH-TEMPERATURE GENERATOR (HTG) IS MORE RELIABLE AND RESILIENT THAN COMPETITIVE FIRE TUBE HTG DESIGNS

Vertical High-Pressure Generator Water Tube Design – Shorter vertical arranged tubes and tube welding points surrounded by solution results in lower thermal expansion on the tube welding points, thus decreasing the probability of leakage.

In addition, the whole tube chamber is surrounded by a solution, so the thermal efficiency is higher, and there is no need for insulation of the chamber.

This vertical design also enables a lower flue gas pressure drop through the unit, contributing to higher electrical efficiency for most turbine generators.

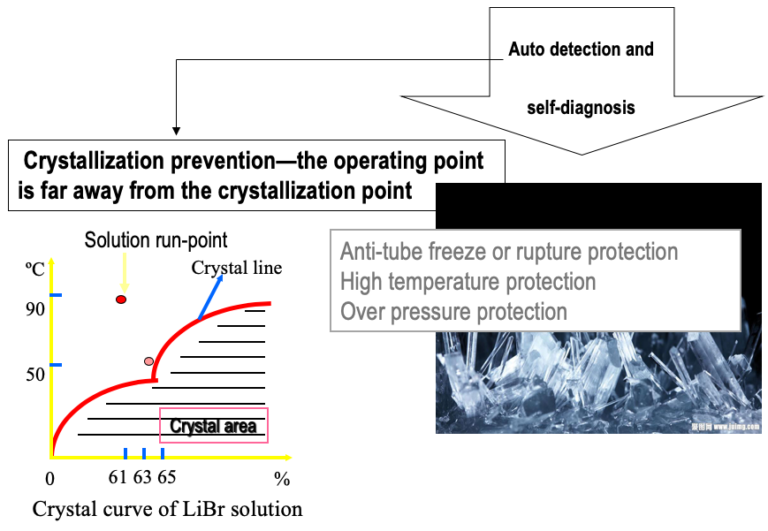

SHUANGLIANG ANTI-CRYSTALLIZATION AND AUTOMATED DE-CRYSTALLIZATION

Solution concentration online monitoring to ensure that it is always safe.

The solution is cycled in series, and the circulation amount is precisely controlled to avoid crystallization.

The level of refrigerant water is automatically controlled. When the concentration of the solution increases, the refrigerant water is automatically bypassed to the absorber to avoid crystallization due to excessive solution concentration.

Fully automatic shutdown dilution cycle to prevent solution crystallization during the shutdown.

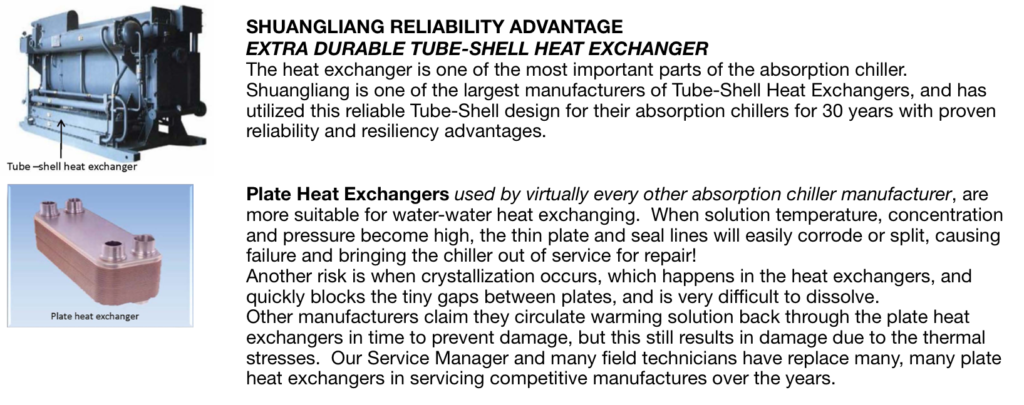

De-crystallization tube temperature detection, limit control, avoiding crystallization. Automatic de-crystallization process, using a high-temperature solution to achieve automatic melting of crystals. This is enabled and possible by the use of the Tube-Shell Heat Exchangers. With Plate Heat Exchangers, the high-temperature solution would cause thermal expansion and damage over time.

The evaporator inlet has a built-in filter device to prevent foreign matter from clogging the heat exchange tube and causing the freezing tube.

High-precision chilled water flow switch, chilled water cut-off safety protection.

Evaporating low-temperature protection to ensure that no freezing occurs in tubes.

Chilled water outlet temperature limit controls low-temperature protection, eliminating the possibility of freezing tubes.

Condenser refrigerant water directly enters the evaporator coolant water tray to prevent the sudden loss of power and cause tube freezing.

Refrigerant pump interlock control directly cuts off the “water source” of the evaporator and breaks the “source” of the frozen tube.

Cooling water pump or cooling water inlet valve interlock control, no absorption, no evaporation, no worry about the frozen tube.

Shuangliang double-effect chiller adopts a parallel flow for cooling water. Therefore, the cooling water inlet temperature has little influence on the absorber, and the chiller has a large adaptability to the cooling water temperature ranges.

For the industrial users who started the operation all the year-round, Shuangliang optimized the structure of the unit and increased the storage capacity of the refrigerant, so that the chiller can adapt to a wider range of cooling water temperature changes.

The automatic control system of the chiller is equipped with cooling water flow control interface. When the temperature of the cooling water changes, the cooling water inlet valve or the water pump inverter can be automatically adjusted to automatically adjust the cooling water flow to improve the cooling water inlet temperature range.

SHUANGLIANG’S unique Evaporator-Absorber-Evaporator arrangement makes the refrigerant vapor flow passage larger, resistance is lower, the evaporation pressure is low, and the cooling efficiency is high.

The evaporator is located in the middle of the two absorbers, and the contact area with the outside atmosphere is small, so the heat loss is low, which is beneficial to the efficiency of the unit. The unit structure is optimized; there is no dead zone in the interior; the unit has a good vacuum, high heat transfer efficiency, and high COP values.

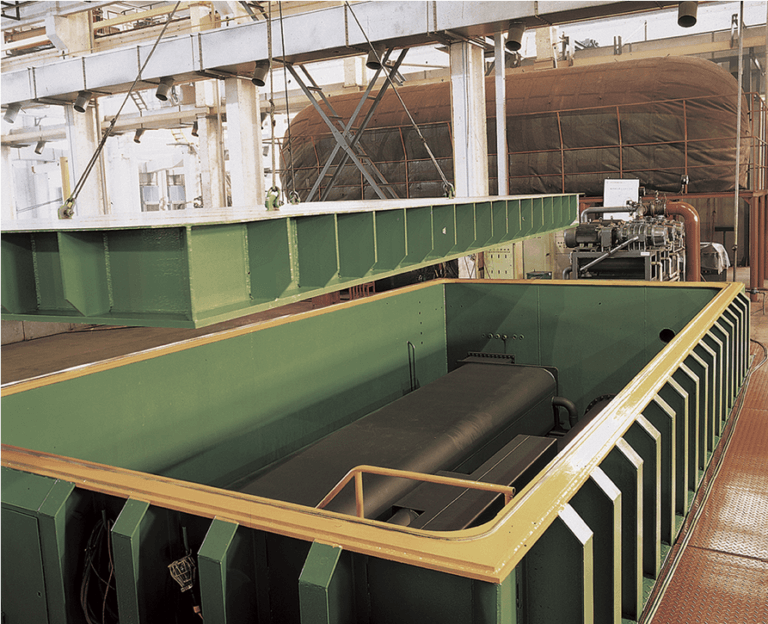

INDUSTRY LEADING RELIABILITY TESTING

The Only Helium Leakage Test for the complete unit in the world (vs. Nitrogen Testing by others). 4 Orders of magnitude tighter tolerance tested than the closest other manufacturers: