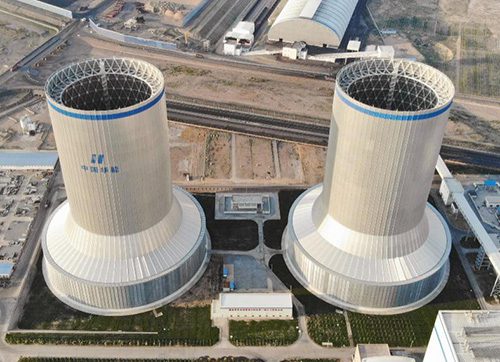

Intelligent Control Steel Structure Dry Cooling System

Shuangliang has been devoted to the basic research and experimental work of steel structure towers for a long time, including wind tunnel test of cooling tower rigid model pressure measurement, wind tunnel test of cooling tower air elastic model vibration measurement, anti-win test of cooling tower cladding, etc., to test and verify the design of steel structure tower and provide technical reserves for the optimization design of steel structure tower.

Information

Technical Capability

Shuangliang has been devoted to the basic research and experimental work of steel structure towers for a long time, including wind tunnel test of cooling tower rigid model pressure measurement, wind tunnel test of cooling tower air elastic model vibration measurement, anti-win test of cooling tower cladding, etc., to test and verify the design of steel structure tower and provide technical reserves for the optimization design of steel structure tower.

In May 2012, it was the first air-cooled steel tower wind tunnel test completed in China, played an important role in engineering design. The research work is innovative, has filled the domestic blank, and has reached the international advanced level overall.

Shuangliang 'holds hands' with Wuhan University of Technology to establish the dry cooling experimental base of the national engineering laboratory for fiber optic sensing technology, and applies the world’s cutting edge ‘Array Grating sensing technology’ and Beidou navigation & positioning technology to the temperature field monitoring & displacement measurement system of steel structure tower, so as to promote the intelligent control of steel structure tower.

2.Six advantages

Compared with the traditional indirect air-cooling system with concrete tower, the intelligent all-steel structure air-cooling system has the following outstanding advantages:

01/ Highly Cost-Effective:

Under the same scale and investment, the cooling performance is improved by 5%. Under the environmental protection policy, the mountain stone forbids mining; the river sand forbids digging, the sandstone price skyrockets, and the cost superiority will become increasingly obvious.

02/ Digital and Intelligent:

The temperature field monitoring technology of steel structure indirect cooling system based on grating fiber technology realizes the fine control of the indirect cooling system, reduces the back pressure of the indirect cooling system in winter by 3 KPa, and saves 4.5 g/kwh of coal consumption.

03/ Short Construction Period, Early Production, and Early Income:

The factory processing of steel tower parts, site assembly, and unit hoisting are less affected by the winter break period; the working period is 1/3 shorter than the traditional concrete tower construction period. Taking 2×660 MW power plants as an example, the construction period can be saved about 6 months (1500 hours at full generation), and the income from early production can reach CNY198 million.

04/ Circular Economy, in Line with National Energy Conservation, and Environmental Protection Policy:

The steel structure tower does not use concrete, uses less sand and stone from the source, protects natural resources, conforms to the national environmental protection policy of green water and green mountain, and conforms to the national policy of vigorously developing steel structure and prefabricated building. High recovery residual value of steel and aluminum plates. The steel structure tower used to replace the concrete tower in a 2×660 MW power plant could reduce CO2 emission by about 36000 tons.

05/ Construction Safety:

The number of high-altitude workers in the construction of steel structure towers is 1/10 of that of concrete towers, which have low safety hidden danger and high safety coefficient.

06/ Get rid of the shackles of the height of the inlet air of the concrete tower, optimize the system design, and save more than 25% of the running electricity charge:

Flexible use of small diameter 6-row pipes with double-sector layout, getting rid of the concrete tower inlet height shackles, and the overall reduction of power plant cold end investment. Reduce the water resistance of the indirect cooling system and save more than 25% of the electricity charge.

Typical Case

Huaneng Group Ningxia Dam Power Plant

Cone straight tower, aluminum alloy skin outside ,170 m tall tower

Installation of Construction Method of Innovative Double Tower Crane

The project won the second prize of 2019 'Science and Technology Progress Award for Electric Power Construction'

Xilinhot Thermal Power Group

2x350MW indirect dry cooling system

The project won the 2019 ‘China Steel Structure Gold Award’ Cone straight tower, aluminum alloy skin outside, tower height 181 m

Installation of construction method for double tower crane