World’s Leading Manufacturer of Absorption Heat Pumps

Shuangliang Eco-Energy is the World Leader in industrial absorption heat pumps (AHP), with over 300 installations in over a dozen countries.

Over 35 years in production and over 500 patents, Shuangliang Eco-Energy absorption chillers have many unique features that have proven to deliver key benefits over alternative manufacturers.

MORE RELIABLE

MORE ROBUST

MORE RESILIENT

MORE EFFICIENT

The 1st Category Lithium Bromide Absorption Heat Pump

Energy Saving 40% Above

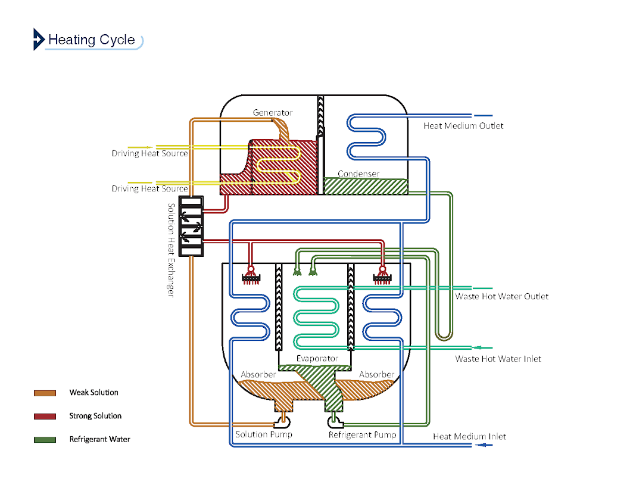

Driven by a high temperature heat source such as steam, high temperature hot water, fuel oil and gas, the 1st category lithium bromide absorption heat pump uses LiBr solution as the absorbent and water as the refrigerant to recover the heat of low temperature thermal source, such as waste hot water, to produce high temperature medium heat required for industrial process or heating in buildings.

It consists of a generator, condenser, evaporator, absorber and heat changer and auxilary parts such as purging pumps (solution and refrigerant pumps), Non-condensable gas such as air is purged by purging unit to keep under high vacuum condition.

Technical Advantage

Driving heat source: steam, water, flue gas, biomass, Cl, gas and etc.

Heat source: Waste hotter (15°C-80°C), mono-component or multicomponent waste gas or liquid.

Using side: Heat medium will be around 50°C or higher than waste heat out (100°C is the highest temp. of heat medium).

Capacity: Single unit can be more than 70MW.

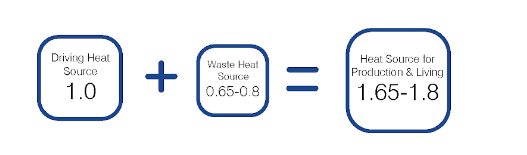

Heat balance

Heating Cycle Features

Evaporator: The heat of low temperature heat source is absorbed by vapor from refrigerant which is sprayed over tubes.

Absorber: LiBr solution is dripped over the tubes to absorber from evaporator and gives off condensing heat to low temperature heat source. The diluted solution is collected and pumped into generator though heat exchanger.

Generator: LiBr solution is heated and concentrated in generator by operating heat source (such as steam) to separate refrigerant vapor. Concentrated solution flows into absorber through heat exchanger to absorb refrigerant vapor form evaporator. High temperature refrigerant vapor goes into condenser.

Condenser: High temperature refrigerant vapor from generator rises the temperature of heating medium. The vapor is condensed into generator, which flows into evaporator.

Heat exchanger: It is used to raise the temperature of auto which flows into generator and decrease that of concentrated solution, the concentrated solution flows back to absorber in order to decrease the amount of energy required by heat pump and improve operation efficiency.

The 2nd Category Lithium Bromide Absorption Heat Pump

Energy Saving 48% Above

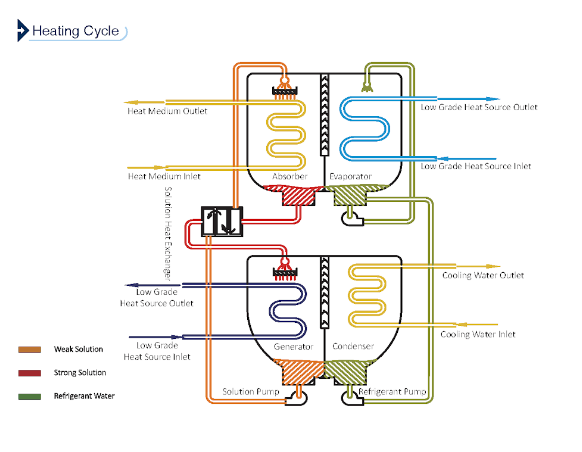

Driven by high temperature heat source, the 2nd category lithium bromide absorption heat pump uses LiBr solution as absorbent and water as refrigerant to recover the heat of low temperature source such as waste heat water to produce high temperature medium water for industrial process heating in building, which can recover the main heat from low temperature source to high temperature one. The 2nd category heat pump differs from the 1st category that requires low temperature cooling water, but no high temperature operating source.

It consists of main parts such as generator condenser, evaporator, absorber and heat exchange and auxiliary parts such as purging unit, hermetically sealed pumps (solution and refrigerant pumps). Non-condensable such as air is purged by purging unit to keep it under high vacuum condition.

Technical Advantage

Heat source: Waste hot water above 60°C, exhaust steam above 90°C, monocomponent or multicomponent gas or liquid.

Using side: Heat medium will be around 40°C higher than waste heat source outlet (170°C is the highest temp of het medium)

Cooling water source: Cooling tower circulating water, production system cooling water and etc.

Capacity: Single unit can be 8MW.

Heat balance

Heating Cycle Features

Evaporator: The heat of low temperature heat source is absorbed by vapor from refrigerant which is sprayed over tubes.

Absorber: LiBr concentrated solution is dripped over the tubes to absorb vapor from evaporator and gives off condensing heat to low temperature heat source. The diluted solution is collected and pumped into general through heater exchanger.

Generator: LiBr solution is heated and concentrated in generator by operating heat source (such as steam) to separate refrigerant vapor. Concentrated solution flows into absorber through heat exchanger to absorb refrigerant vapor from evaporator. High temperature refrigerant vapor goes into condenser.

Condenser: High temperature refrigerant vapor from generator raises the temperature of heating medium. The vapor is condensed into refrigerant which flows into evaporator.

Heat exchanger: It is used to rase de temperature of solution which flows into generator and decrease that of concentrated solution, then concentrated solution flows back to absorber in order to decrease the amount of energy required by heat pump and improve operation efficiency.