Hybrid Cooling Tower

With its great success in air cooled condenser (ACC), 40 years in vacuum heat exchange, and 20 years in dry cooling technology, Shuangliang is now entering to a new application - circulating water cooling for various industries. The newly developed SGSL series hybrid cooling tower is aiming at saving water consumption for different industries, like food and beverage, pharmaceutical, steel, chemical, electronics, etc.

Information

Traditional cooling methods for industrial circulating water

A large amount of heat is produced in the production process of the industrial field, which needs to be cooled by the circulating water-cooling system. The traditional cooling method is an open-circle water cooling tower.

Problems with traditional cooling methods

- High water consumption (1.5%~1.8% of circulating water), serious waste of water resources, not in compliance with environmental policy;

- High operating water consumption and sewage treatment cost, poor economy;

- Winter operation produces a large number of white fogs, becomes the carrier of haze, and ‘culprit’ of these;

- Winter white fog forms snow and frost microclimate, resulting in safety risks.

With the tightening of environmental protection policies, traditional circulating water-cooling methods will be replaced. Shuangliang's energy-saving, water-saving, and mist-eliminating industrial circulating water system aims to achieve the dual benefits of environmental protection and economy.

1.Hybrid Cooling Tower

Structure

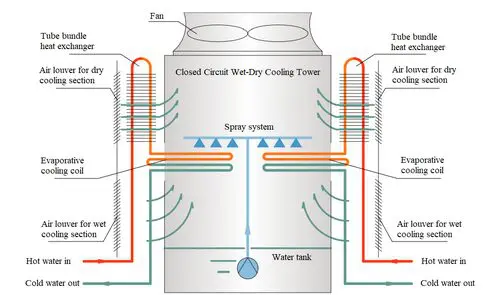

Combination of the air-cooling radiator (finned tube) and evaporative cooling coil (smooth tube) in one cooling tower with novel structure design The heat dissipation of the dry cooling section is vertically arranged outside the tower, and the evaporative cooling coil section is horizontally arranged inside the tower. Both sections work in series at the waterside and in parallel at the wind side.

Function

Water saving

The hybrid cooling tower operates in a seasonal cycle with two main modes: Winter mode, and Summer mode.

In summer, the main operating condition is to meet the cooling water temperature by opening the wet cooling section air louver and closing the dry cooling section air louver to increase the windspeed through the wet cooling section, giving full play to the cooling capacity of evaporative cooling in summer and meet the water temperature requirements. In winter, the main operating condition is mist elimination and water saving by turning down the wet cooling section air louver and turning up the dry cooling section air louver to increase the wind speed through the dry cooling section, giving full play to the dry cooling capacity, and achieve the maximum water saving.

What about in Spring and Autumn? It will be inter-state between Summer and Winter mode, i.e., the air louver openness of both sections is well manipulated by the PLC or DCS automation system to guarantee designed cooling water temperature and save water as much as possible at the same time.

Plume abatement

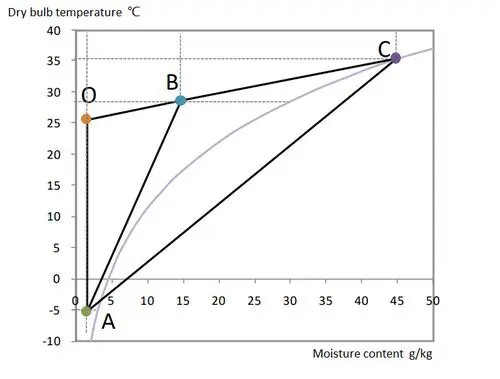

The circulating water enters the tube bundle in the dry cooling section for cooling and then enters the wet cooling section for cooling. The high-temperature and high-humidity air (state point C)generated by evaporative cooling in the wet section is mixed with the heated dry and hot air in the dry section to reduce the moisture content. It is discharged after reaching state B. The mixing line (BA line) does not intersect with the saturation line to realize mist elimination. This technical route can eliminate fog all year round.

Main Features

01/ Combined air-cooling and evaporative cooling technology

Air cooling and water cooling are integrated, and the switching and joint operation of air cooling and water cooling are used to ensure the stability of outlet water temperature and achieve the effect of water saving and mist elimination. The economic benefits of water saving are considerable, and the benefits of environmental protection are obvious.

02/ L-type dry and wet combined system

The air-cooling and water-cooling adopt the type layout of the invention patent: the air-cooling section is arranged vertically outside the tower, and the water-cooling section is arranged horizontally inside the tower. The circulating water is cooled by the air-cooling section first and then by the water-cooling section. The whole process is in the L type.

03/ Low thermal resistance and high heat transfer coefficient

The heat transfer surface of the fin of their-cooled tube bundle is slotted to strengthen the turbulence, and the heat transfer coefficient is high. The fin is closely combined with the base tube after expansion, and the thermal resistance is low. For long-term operation, because the spring effect is still tight, the heat exchange efficiency decays slowly.

04/ Optimized pipeline process design

The double-flow counter cross-flow can make the heat-transfer coefficient higher.

05/ Low wind-resistance and low power consumption

The fins between each row of the cooling tube bundle are continuous, and the wind resistance of the air-cooled tube bundle is low. The air-cooling tube bundle is vertically arranged outside the tower, the air-cooling section and water-cooling section are connected in parallel on the wind side, and the system wind resistance is low. Compared with other water-saving demisting towers, the fan power consumption is about 30% lower.

06/ High water-saving rate

The air-cooling tube bundle is arranged on both sides outside the tower, which can be expanded by increasing the quantity of fans in the single tower and the area of the air-cooling tube bundle, so as to give full play to the role of the air-cooling tube bundle and reduce water evaporation, and achieve a water-saving rate of 85% at most.

07/ Fog elimination throughout the year

The dry, hot air passing through the air-cooling tube bundle is mixed with the saturated wet air of the water-cooling tube bundle to reduce its moisture content, and there will be no fog when entering the atmosphere so as to ensure fog elimination throughout the year.

08/ Intelligent automatic control technology

The opening and closing of shutters of the air-cooling tube bundle and water-cooling tube bundle, the frequency variation of the motor and the start and stop of the spray water pump can be adjusted automatically according to the inlet and outlet water temperature and ambient temperature.

The client can choose to access the “Shuangliang cloud platform” developed by Shuangliang according to the characteristics of this product to upload the data to the cloud, which can realise the functions of remote Internet real-time monitoring, WeChat receipt of fault information, cloud data backup, big data analysis, predictive maintenance, equipment health analysis, etc.

2. V Type Dry Cooling Tower

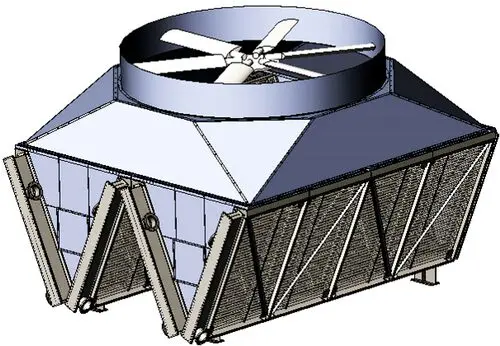

V Type Dry Cooling Towers can be used independently or in upgrade projects in combination with existing wet cooling towers to save water consumption.

System Composition

V separate water-saving and fog-removing system consists of the finned tube bundle, circulating water pipeline, and fan group. V air cooler and mechanical ventilation water cooling tower are arranged independently and connected by circulating water pipe. The circulating water in winter is cooled only by a V type of air cooler, and no water vapor evaporates; the circulating water in spring and autumn is cooled first by a V type of air cooler, then cooled by mechanical ventilation water cooling tower, and the amount of water vapor evaporates is less; the water-cooling tower with mechanical ventilation is used in the summertime with high temperature.

Main Features

01/ Modular, easy to install

V air cooler adopts a self-supporting structure, modular design, and easy and quick installation.

02/ Maintenance convenience

Tube bundle horizontal arrangement, removable cover plate tube box, easy-to-tube bundle internal cleaning and maintenance.

03/ High annual water-saving rate

The circulating water is cooled only by the V-type air cooler in winter, without evaporation of water vapor; the circulating water in spring and autumn is cooled by the V-type air cooler, the cooling load of the mechanical ventilation water cooling tower is partial, the water consumption is low, and the annual water saving rate reaches 60%.

04/ Anti-freeze property

Adopt a special anti-freezing design; winter operations do not need to set blinds; anti-freezing is safe and reliable.

05/ Separate layout

The V-type air cooler is arranged independently from the mechanical ventilation water cooling tower. According to the characteristics of the site, all available space and flexible arrangements can be made. If the area is tight, the V-type air cooler can be arranged overhead on the road.

06/ Applicability

Suitable for the water-saving transformation of water-cooling towers.

3. Mist Spray Dry Cooling Tower

System composition

The spray dry cooling system is composed of a stainless-steel tube radiator, louver, circulating water system, expansion water tank, spray cooling system, fan group, and so on. The air-cooling radiators are arranged vertically outside the tower, which depends on the air to cool the circulating water, but when the ambient temperature is high, water spray on the outer surface of the radiator is used to assist the cooling.

Main Features

01/ Low water consumption

In the whole year, only in summer, high temperatures with short-time spray cooling will apply; the annual water-saving rate is more than 95%.

02/ Maintenance convenience

The radiator is arranged vertically outside the tower, which is only composed of an air-cooling radiator, a fan system, and a closed circulating water pipeline system. The maintenance equipment is less, and there is no need for spray water quality management. The operation and maintenance are simple and convenient with less operation and maintenance costs.

03/ Low operating cost of circulating water system

The circulating water system is a closed system with low lift and low power consumption.

04/ Double Process Reverse Cross-Flow Structure

The design of a double-flow reverse cross-flow structure makes the total heat transfer coefficient of the air-cooling radiator higher than that of a single-flow cross-flow arrangement, and the total heat transfer area can be reduced by about 20%.

05/ Back-to-back arrangement, small footprint

One-side air inlet and back-to-back arrangement are adopted to reduce the area, and the influence of hot air reflux is small.

06/ Applicability

Suitable for high effluent temperature (above 38℃) of circulating water.

Typical Case

Inner Mongolia Baotou Monocrystalline Silicon Project

Inner Mongolia Baotou Monocrystalline Silicon phase I Project

Xinjiang Xinlianxin Coal Chemical Project

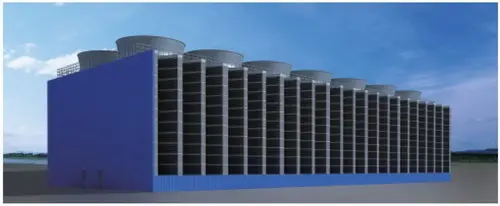

V Type Separation Water Saving & plume-abatement System

A total of three reconstruction projects, the total amount of water 60500 m3/h

Adopt V type separate water-saving and mist-removing system, modular design, flexible arrangement, easy installation, convenient maintenance

While eliminating the white fog in the cooling tower in winter ,4.73 million tons of evaporative water and 1.58 million tons of sewage were reduced throughout the year. It has great social and economic benefits

Chifeng Yun Copper Nonferrous Metals Co., Ltd.

Mechanical ventilation dry air cooling tower

Stable and reliable operation since October 2018

The annual water-saving rate is over 95%, and the water-saving effect is remarkable